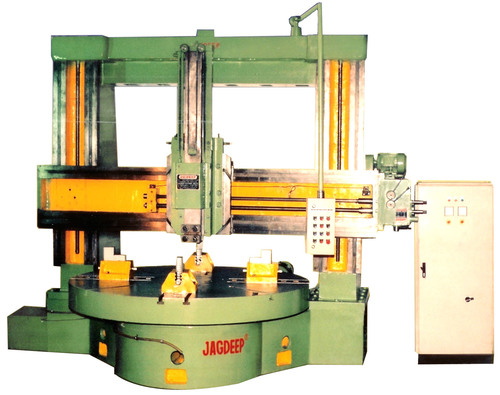

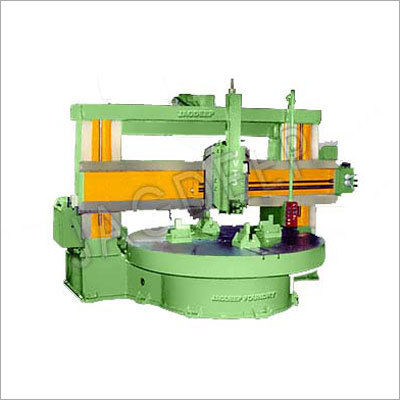

Vertical Turning Lathe VTL 1000 mm

Product Details:

- Product Type Vertical

- Material Cast Iron

- Cutting Thickness Up to 100 mm

- Cutting Speed 30 - 300 RPM (variable)

- CNC Or Not Normal

- Automatic Grade Automatic

- Control System Manual / Electrical

- Click to View more

Vertical Turning Lathe VTL 1000 mm Price And Quantity

- 1 Unit

- INR

- 2.2 kW

- 110 mm

- Provided

- Gear Drive

- 750 mm

- Centralized automatic lubrication

- 0.01 mm

- 2

- 15 kW

- 4 Jaw Independent

- 900 mm

- Box Type, extra heavy duty

- 3000 kg

- Heavy duty turning, boring, facing and grooving of large workpieces

Vertical Turning Lathe VTL 1000 mm Product Specifications

- Rigid structure, smooth operation, long service life

- Cast Iron

- Vertical

- 415 V / 3 Phase / 50 Hz

- Up to 100 mm

- Normal

- 30 - 300 RPM (variable)

- Manual / Electrical

- 9000 kg

- 3700 mm x 2500 mm x 3200 mm

- Industrial Grey and Blue

- Max Turning Diameter: 1000 mm, Max Turning Height: 750 mm

- 1000 mm

- Automatic

- 2.2 kW

- 110 mm

- Provided

- Gear Drive

- 750 mm

- Centralized automatic lubrication

- 0.01 mm

- 2

- 15 kW

- 4 Jaw Independent

- 900 mm

- Box Type, extra heavy duty

- 3000 kg

- Heavy duty turning, boring, facing and grooving of large workpieces

Vertical Turning Lathe VTL 1000 mm Trade Information

- As per requirement Per Month

- As per requirement Months

Product Description

| Descriptions | JVT-1 |

| Max. Turning Diameter | 1100 mm |

| Table Diameter | 1000 mm |

| Max. Working Height | 600 mm |

| Max. Vertical Travel of Ram | 500 mm |

| Swivel Angle of Ram Head | ± 30° |

| No. Of Table Speeds | Stepless Infinitely Variable Speed With AC Variable Frequency Drive |

| Range of Table Speed RPM | 6-60 rpm |

| No. of Feeds Vertical/Horizontal | 6 |

| Range Of Feeds Vertical / Horizontal (mm/min) | 3-12 |

| Rapid Traverse of Head (mm/min) | 300 mm |

| Main Motor | 7.5 Hp |

| Ram Feed Motor | 3 Hp |

| Auto Lifting of Cross Rail Motor | 3 Hp |

Standard Accessories.

Auto Feed Of Ram Head: Gear Box for Auto Feed Ram Head both Vertical & Horizontal will be provided with Motor.

Lubrication: Auto Lubrication System a Bed Guide Ways is provided with the machine.

Complete Electricals

Control Panel

One Tool Post (Ram Head)

Leveling Bolts

Leveling Plates

Machine Light

Set of 4 Jaws for Work Piece Clamping

Exceptional Load Capacity and Precision

The VTL 1000 mm stands out for managing heavy workpieces with a maximum table load of 3000 kg and maximum swing diameter of 1000 mm. Its two-tool post configuration and precise spindle bore allow for seamless operations like turning, boring, and grooving, ideally suited for industries handling large cast iron or steel components. Variable cutting speeds further enhance performance across a range of materials.

Rigid, Reliable, and Easy to Operate

Engineered with a box-type bed and an extra heavy-duty frame, this lathe ensures stability and longevity even under continuous industrial use. Equipped with centralized automatic lubrication and a coolant system, the machine minimizes downtime and maintenance, delivering reliably smooth operations. The intuitive control systemavailable in both manual and electrical operationsupports operators in maximizing productivity.

FAQs of Vertical Turning Lathe VTL 1000 mm:

Q: How is the Vertical Turning Lathe VTL 1000 mm typically used in industrial applications?

A: The VTL 1000 mm is primarily used for heavy-duty turning, boring, facing, and grooving operations of large workpieces, especially in manufacturing sectors such as automotive, machinery, and energy. Its robust table and high-capacity capabilities make it suitable for precision machining of cast iron, steel, or similar tough materials.Q: What are the main benefits of using this model for large-scale machining tasks?

A: Key advantages include its high load capacity (up to 3000 kg), large swing diameter (1000 mm), precise setting (0.01 mm), and rigid box-type bed that ensures stability and accuracy. Automatic lubrication and a centralized coolant system enhance operational efficiency, while variable cutting speeds accommodate a range of material types for optimum results.Q: When is it recommended to use a 4 Jaw Independent chuck in machining processes?

A: The 4 Jaw Independent chuck is ideal for holding irregularly shaped or asymmetrical workpieces. It provides individual adjustment for each jaw, ensuring a secure grip and accurate centering, which is essential for heavy-duty turning and advanced machining tasks required by this VTL.Q: Where can this VTL model be installed and what are its space requirements?

A: This VTL is designed for installation in industrial workshops or manufacturing plants with sufficient space to accommodate its footprint of 3700 mm x 2500 mm x 3200 mm. The machines robust construction suits environments that handle heavy-duty or large-scale machining projects.Q: What is the process for maintaining the VTL 1000 mm for optimal performance?

A: Maintenance is streamlined with its centralized automatic lubrication system, which ensures all key components remain properly lubricated. Regular inspections of the gear drive, chuck, and electrical systems, along with timely coolant replenishment, are recommended to ensure the machine continues operating smoothly and reliably.Q: How does the manual/electrical control system enhance operator usage and safety?

A: The dual manual/electrical control system provides flexibility for operators to manage machining operations according to the requirements of each project. This configuration supports precise adjustments, safer handling of large workpieces, and adaptability to either automated or hands-on processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS